Mechanical Scans

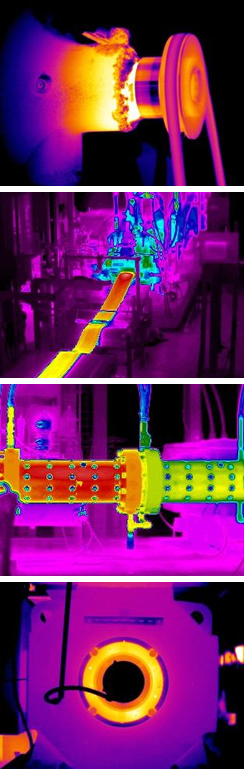

In mechanical equipment, high temperatures are usually created by friction resulting from improper lubrication, misalignment, worn components, damaged bearings or mechanical loading anomalies. 41% of motor failures happen from bearings and 37% from the stator. When components fail, they typically overheat first. Using infrared technology, we can quickly identify the problem so corrective action can be taken to prevent a costly failure and/or replacement.

Equipment that can benefit from and infrared inspection include:

- Motors and bearings

- Pumps and couplings

- Boilers, pipework, and ductwork

- Freezers

- Steam lines and traps

- Process (injection molding, extruders, ovens)

We inspect your equipment under normal loads and operating conditions, so you don’t have to disrupt your service and production schedules. We want to minimize or eliminate costly downtime.

With an infrared inspection, potential problems can be easily pinpointed and repaired prior to failure.

Call or e-mail us to schedule a no-cost consultation.